The Rocket So Powerful It Shook Buildings Three Miles Away | Saturn V And The Future Of Space Travel

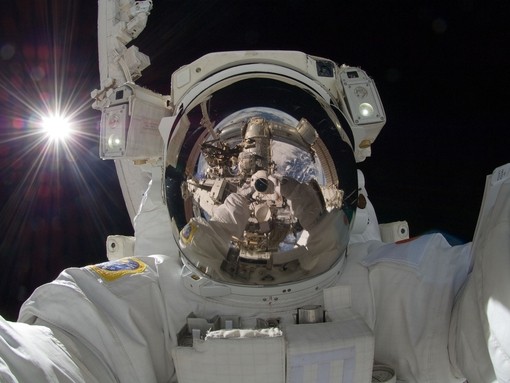

This year marks 50 years since man set foot on the moon for the first time in history. To mark this momentous engineering and scientific milestone, we’re looking back at the history of engineering in space travel and also into the next 50 years.

In this article we look at the launch of the rocket that would propel man to a new world for the first time, and how the seeds of the future of space travel may well have been planted in that very same era.

An Eagle Lands

Thursday November 9th1967 proved to be a pretty significant day in American pop culture history. The very first issue of the legendary Rolling Stone magazine was quietly published as a small regional newspaper in the San Francisco Bay Area. Meanwhile, 2,500 miles away in Florida, the largest, heaviest and most powerful rocket built to this day lifted off for the very first time from Launch Complex 39A at the Kennedy Space Centre, Merritt Island.

Apollo 4 would be the first un-manned test flight of the Saturn V rocket, a launch vehicle that was being designed and built with a single goal in mind – to put man on the moon and return him safely back to Earth. Weighing in at 37,000kg, the lift-off of Apollo 4 was so loud it shook ceiling tiles loose at the Launch Control Centre three miles away from the launch site. Standing 363ft (110.6m) tall, the vehicle was split into three main stages, each one being jettisoned as they ran out of fuel, firing the Command Module (in which the three astronauts would travel for four days and 384,400km to the moon) to a speed of 4.13km/s in the vacuum of space.

The test launch was a success and paved the way for the continuation of the Apollo program. Fast forward to Wednesday 16th July 1969 and Apollo 11 sat on the very same launch pad as Apollo 4, waiting with a crew of Neil Armstrong, Buzz Aldrin and Michael Collins on-board. Four days later, Armstrong would make history.

The Engineering Behind The Rocket

The origins of the Saturn V rocket began in 1946, with the US government rounding up hundreds of German engineers who had developed the rocket and missile technology that the Nazi war machine had used to devastate Europe during World War II. The lead engineer, Wernher von Braun, had worked on the V-1 and V-2 rockets and was quietly spirited away into a prototype version of NASA to advance their own program ahead of the Soviets.

Assembled in what is still the largest single storey building in the world, each Saturn V launched (there were thirteen in total) cost the equivalent of $750million in today’s money and the project went from first engineering design on a drawing board to launchable vehicle inside just six years.

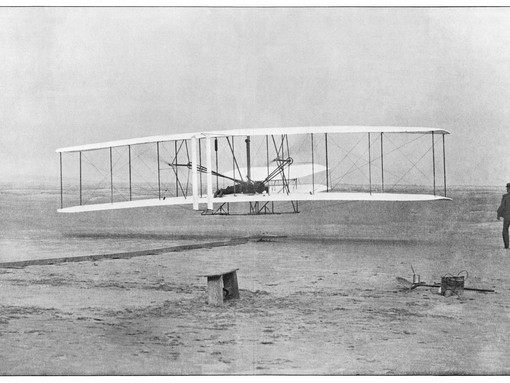

The first stage of the rocket, responsible for the initial part of the launch, comprised five F-1 engines, each 12.5m in diameter and providing 1.7million lbf of force. The F-1 engine is still the most powerful single nozzle liquid fuelled rocket ever flown. The fuel pump delivered 15,471 US gallons (58,560 litres) of rocket grade kerosene per minute while the oxidizer pump delivered 24,811 US gal (93,920 l) of liquid oxygen per minute. In simple terms, it burnt more fuel in a single second than was burned during the first solo crossing of the Atlantic in a powered aircraft.

With the Apollo programme cancelled after Apollo 17, the Saturn V rocket was officially retired after one final launch for Skylab in 1973. To this day its scope and power has not been equalled.

TOP BLOG: Bloodhound SSC | The Rocket-Powered Fighter Car

2069?

With the Saturn V long gone and no further manned missions to other worlds happening in the last 50 years, what is the future of rocket-powered travel?

The rocket of the future might actually have been engineered in the past. Even from back in the 1960’s at the time of Apollo, NASA was experimenting with using a nuclear reactor to heat a reaction mass like hydrogen to expel it from a thrust chamber as fast-moving gas – hence, a nuclear rocket. The Nuclear Engine for Rocket Vehicle Application (NERVA) program was closed in 1972 once the moon landings were cancelled and a manned visit to Mars fell from the agenda.

Orion was a spaceship that was being developed in the ‘60s by physicist Freeman Dyson and nuclear weapons designer Ted Taylor.Orion was to be powered by small nuclear explosions – specialised bomblets that would go off below a big pusher plate, shoving the spacecraft in the opposite direction. The spacecraft worked better when it was large, and in theory could have been fast enough to go anywhere in the solar system within a good timeframe. Furthermore, the technology allowed for high thrust with high efficiency, something missing from other types of propulsion.

NASA seems to be reigniting its interest in nuclear rocket technology, with $19million set aside for funding, looking towards a demonstration as early as 2024.

Nuclear rockets could do to space travel what the steam engine did for ocean exploration.