Contents

Morson Projects have a new client, who goes by the name Santa Claus, this is their report:

We pride ourselves on our consistent delivery of engineering services across the range of industries we operate within; tailoring our services to meet clients’ specific needs.

Our new client Mr S Claus operates in the specialised sector of global festive cheer and gift delivery, fulfilling this service worldwide to time, quality and no cost. He has an excellent workforce including suitably qualified and experienced manufacturing elves as well as an excellent mode of transport with innovative propulsion.

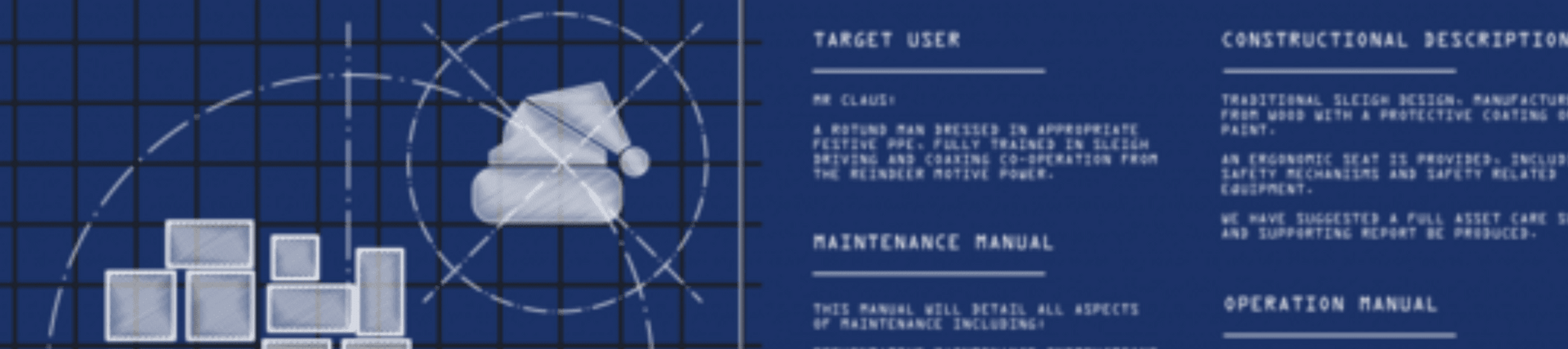

As part of Mr S Claus’ continual improvement, he has tasked our Technical Services Department to ensure that all technical documentation is in place in accordance with his legal obligations to provide fit for purpose documentation for personnel who interface with his sleigh.

As well as the above, Mr Claus must take various other aspects into consideration. From Database organisation to sleigh lifecycle care, to composite materials.

The Morson Projects team gives us an overview:

Santa’s Database

Dan Robinson – Power Apprentice:

Now we all know Santa Claus likes to be efficient by delivering presents all around the world in one night! That’s why good old Kris most likely uses a database to store information, such as the addresses of all the good boys and girls.

Databases are brilliant for storing information to be put through an algorithm which can then be used to provide Santa and his reindeer with the most effective route to deliver all those presents in time for Christmas. He could ask his elves to create a database before Christmas including children’s names, where they live (GPS coordinates) and what presents they are getting.

Sleigh Lifecycle Care

Freyja Ingham – Asset Care Engineer

I would set about creating an inspection schedule listing all assets on the sleigh in a logical order. I would then carry out an inspection taking note of anything which is showing signs of degradation, anything which is set up incorrectly and anything which has the future potential to cause harm to people or the surrounding equipment. This inspection would help in the maintenance of the sleigh, pinpointing any areas of concern which could be degrading faster than others, for example, the sleigh runners and fixing arrangements, allowing the maintenance team to fix any faults prior to them causing any kind of danger. As the documents may need to be for anybody to use all around the world I might think of including images of the item to be inspected so anybody anywhere could pick it up regardless of language barriers.

Lighting up The Sleigh

James Adshead – Power Apprentice:

The only source of light that Santa’s sleigh emits is from Rudolph’s nose, during the busiest night of the year he may need extra lights to help the night run a bit smoother.

I propose that Santa’s sleigh should be fitted with a variety of LED lights for him to carry out other tasks within the Sleigh, for example, he will probably be stepping out onto a roof when delivering presents. In order to combat this, a small strip of LED running lights can be installed on the underside of the sleigh illuminating the ground around and underneath him. This not only makes it easier to land the sleigh but also makes it a lot safer for Mr Claus when he is departing the sleigh to deliver presents, meaning there is less of a chance that Santa will slip and hurt himself, ruining Christmas!

As well as this, he may need some light within the Sleigh for him to see the presents that are in the back, helping him to identify the correct presents at the correct houses.

Traditionally Santa’s sleigh is made from materials such as wood and due to the simplicity of the design, there are no electrical components or systems fitted. Thankfully, installing these LED’s means no changes need to be made to the current structural design of the sleigh. The battery that powers the LED’s can be hidden away under his seat and only small wires are needed to run between this battery and the lights. If he wanted he could also have a switch that allowed him to turn these LED’s off and on at will. If he didn’t want to worry about whether the battery was going to run flat he could attach a small set of blades (with a diameter of no more than 30cm) onto the side of the sleigh, which rotates due to the air passing through them as he flies between each house. These could be attached to a shaft which leads into a small generator, thus creating the charge required to prevent the battery running flat.

Hopefully, these changes will make Santa’s deliveries on Christmas Eve run smoother and prevent any accidents from happening which could put Christmas in jeopardy.

Composite Materials

Stuart Taylor – Graduate Design Engineer

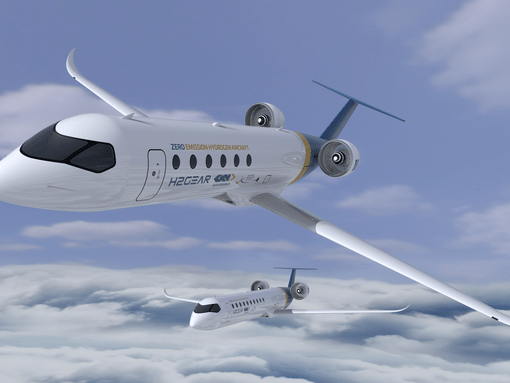

For Santa’s Sleigh to fly all night, it must be lightweight so that the reindeers don’t get too tired! The sleigh would be made from composite materials to ensure it was not only light but also strong and durable to do so many miles.

Paulo Venancio – Aerospace Project Manager & Mark Davies – Aerospace Chief Engineer

Santa’s sleigh blades are made of ceramic composite to manage the high temperature due to travelling at the speed of light. The sleigh structure is a monocoque, designed with lightweight carbon boron materials. The fabrics are specifically weaved by elves in Finland and the resin comes from the undergrounds of the artic…

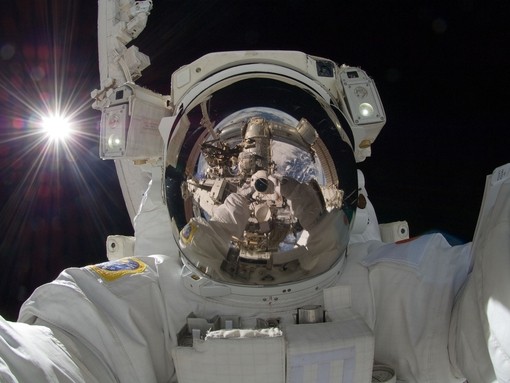

Also, Santa wears a Kevlar suit to protect him from any bullets from children that didn’t get the presents they want.